You’ve been selling generic fashion dropshipping for six months. Margins hover around 20%. Every time you find a winning product, three competitors pop up selling the identical item. You’re trapped in a price war you can’t win.

Then you see successful clothing brands on Instagram charging 3x what you charge for similar products. The difference? They have branded labels, custom packaging, and cohesive brand identity. Customers pay premium prices because they’re buying a brand, not just fabric.

Importing clothes from China with your own brand transforms you from commodity reseller to fashion brand owner. But the apparel industry has unique complexities that destroy beginners: sizing inconsistencies, fabric quality issues, import regulations, and MOQs that tie up serious capital.

Let me show you exactly how clothing importation works in 2026, what makes apparel different from other products, and how to avoid the expensive mistakes that kill fashion brand attempts.

Why importing branded clothing is different from other products

Apparel isn’t like phone cases or fitness equipment. Unique challenges make it simultaneously more profitable and more complex.

Sizing and fit consistency create or destroy brands

A phone case either fits a phone or doesn’t. Objective pass/fail. Clothing fit is subjective, varies by body type, and inconsistent sizing between batches destroys customer trust.

Your size medium from production run one fits differently than size medium from run two. Customers notice. They don’t reorder.

Getting sizing standardized and consistent across production runs requires detailed tech packs, grading standards, and quality control that verifies measurements match specifications.

Fabric quality directly impacts perceived value and returns

Cheap fabric feels cheap. Photos can hide this. Customers discover it on arrival. Return rates spike. Reviews tank.

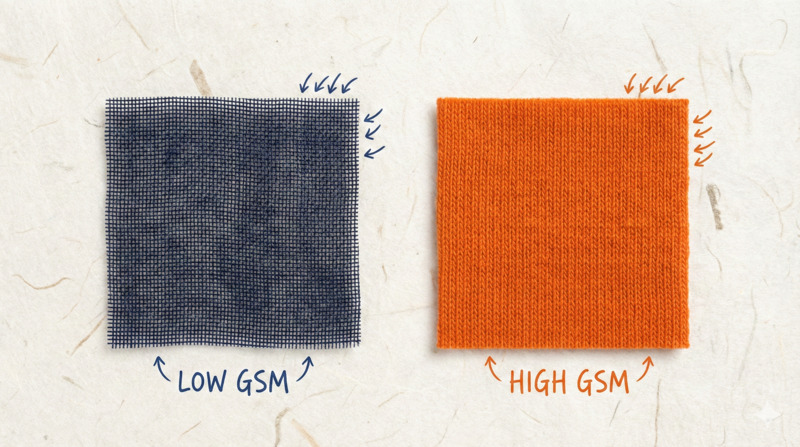

Fabric weight, composition, finish, and construction quality determine whether customers perceive your $40 hoodie as premium or cheap. This requires understanding GSM, fabric composition percentages, and quality grading.

Most beginners can’t evaluate fabric quality from samples, leading to expensive inventory mistakes.

Import regulations for textiles are stricter than general goods

The US requires country of origin labeling sewn into garments. The EU has strict regulations on textile composition disclosure and chemical content. Flammability standards apply to children’s clothing.

Non-compliant imports get held at customs, returned, or seized. Your investment vanishes because you didn’t understand textile import requirements.

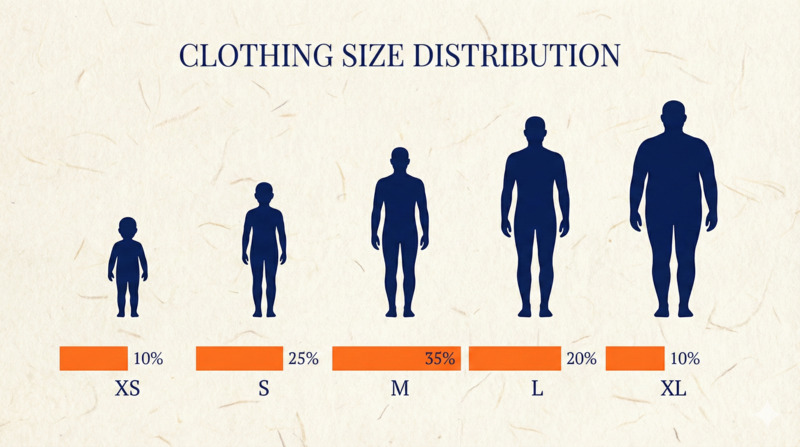

MOQs are higher because apparel requires multiple sizes

You can’t order 100 units of “medium.” You need 100 units distributed across XS, S, M, L, XL. Each size counts toward minimums.

If factory MOQ is 500 units and you need five sizes, you’re ordering 100 per size minimum. Predicting size distribution without sales data means inventory imbalances you can’t sell.

The July 2026 customs reforms hit apparel especially hard

EU import regulations require IOSS registration for all e-commerce shipments, with VAT applied at point of import. US tariffs on Chinese textiles range 15-30% depending on fabric type and HS code classification. Non-compliant imports get held at customs. Research destination market requirements before production.

The realistic process for importing branded clothing

Step one is choosing apparel categories that support your brand positioning

Not all clothing categories work equally well for new brands. Basics like plain t-shirts compete on price, making branding difficult. Fast fashion trends require constant new designs.

Successful new brands focus on specific niches: sustainable activewear, plus-size fashion, modest fashion, technical outdoor wear, or aesthetic-specific clothing (streetwear, minimalist, etc.).

Choose categories where brand story and identity add value beyond the fabric itself.

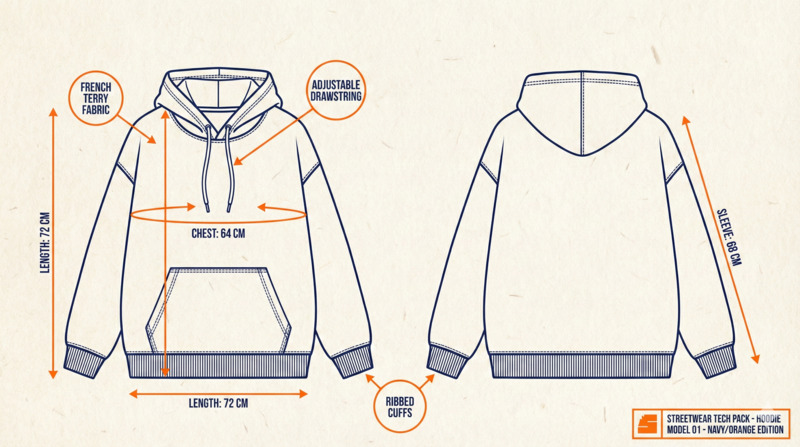

Step two is creating tech packs with actual specifications

Tech packs are detailed technical documents showing measurements, fabric specs, construction details, labeling placement, and quality standards. They’re the blueprint factories use for production.

Generic descriptions like “black hoodie with my logo” don’t work. You need sleeve length, shoulder width, chest measurements, hem type, fabric composition, zipper specifications, and placement diagrams.

Professional designers create tech packs. If you lack design expertise, work with freelancers or sourcing agents who handle technical documentation.

Step three is sourcing factories that specialize in your garment type

Not all garment factories produce all clothing types. Knit fabric specialists differ from woven fabric manufacturers. Activewear factories use different equipment than dress shirt producers.

You need manufacturers with the right equipment, expertise, and capacity for your specific garment category. A factory that makes excellent hoodies might produce terrible dresses.

Sourcing agents with established apparel networks know which factories excel at which categories, eliminating trial-and-error.

Step four is understanding fabric selection and quality grading

Cotton isn’t just cotton. Jersey knit differs from french terry. 180 GSM fabric feels different than 220 GSM. Combed cotton is softer than carded cotton.

These specifications determine how garments feel, drape, wear, and wash. Getting fabric selection wrong means products that look good in photos but disappoint in person.

Order swatches of proposed fabrics. Feel them. Wash them. Evaluate how they hold up. This tactile evaluation prevents expensive mistakes.

Step five is sample production and fit testing

Order samples in all sizes you’ll offer. Test them on actual people representing your size range. Verify measurements match tech pack specifications.

Check stitching quality, seam strength, label placement, fabric hand feel, and construction details. Wear samples. Wash them multiple times. Evaluate durability.

One round of samples costs $100-$300. One bulk order of ill-fitting garments costs thousands. Always sample.

Step six is navigating apparel-specific import compliance

Clothing must have sewn-in labels showing country of origin, fabric content, and care instructions in the destination language. The US requires RN (Registered Identification Number) or company name and address.

Children’s clothing faces additional safety testing and certification requirements. Certain fabrics require flammability testing.

Research destination market requirements before production. Non-compliant garments get rejected at customs.

Step seven is establishing size distribution based on market data

Without sales history, predicting size ratios is guessing. Industry standards suggest roughly: XS 10%, S 20%, M 35%, L 25%, XL 10% for US markets.

EU markets skew slightly smaller. Asian markets significantly smaller. Adjust based on your target demographic and comparable brand data.

Order conservatively first run. Scale sizes based on actual sales data in subsequent orders.

Step eight is managing production quality control for apparel

Garment QC inspects random samples from production runs for measurements, stitching quality, fabric defects, color consistency, and construction issues.

AQL (Acceptable Quality Limit) standards determine acceptable defect rates. Common standard is AQL 2.5, meaning 2.5% defect rate is acceptable.

Professional inspectors catch issues before shipment. DIY importers discover problems after investing in inventory.

Apparel-specific challenges and how to solve them

Size inconsistency between production runs

Even with detailed tech packs, slight variations in cutting, sewing, or fabric batches create size inconsistencies. This is inevitable in garment manufacturing.

Solution: Maintain relationships with consistent factories. Reorder from same manufacturers. Conduct QC on every production run to verify measurements match standards.

Color matching across fabric batches

Fabric dye lots vary slightly. Your “navy blue” from batch one might not perfectly match batch two. This creates customer complaints about inconsistent products.

Solution: Order enough fabric for multiple production runs simultaneously when possible. Store excess fabric for reorders. Accept that perfect color consistency across months is unrealistic.

Seasonal inventory risk

Fashion has seasons. Hoodies sell in fall/winter. Tank tops in spring/summer. Ordering 1,000 units in wrong season creates dead inventory.

Solution: Order seasonally appropriate inventory 3-4 months before peak season. Start small. Scale based on actual demand rather than optimistic projections.

Return rates higher than other product categories

Apparel return rates run 20-40% compared to 5-15% for other products. Sizing issues, fit dissatisfaction, and color perception differences drive returns.

Solution: Clear size charts with measurements. Detailed product photos showing fit on different body types. Generous return policies that build trust. Factor return costs into pricing.

Trend sensitivity and obsolescence

Fashion trends change. A style popular today becomes dated within months. Inventory that doesn’t sell becomes unsellable.

Solution: Focus on timeless basics or evergreen styles rather than fast fashion trends. Order conservatively. Sell through inventory before scaling aggressively.

MOQ navigation and capital requirements for clothing

Typical apparel MOQs range from 300-1,000 units total

Simple garments with minimal customization might accept 300 units. Complex designs or multiple colorways demand 500-1,000 units.

At $8-$15 per unit, this is $2,400-$15,000 in product costs before shipping, duties, and fulfillment.

Per-color and per-size MOQs compound quickly

If you want three colors and five sizes, you’re creating 15 SKUs. If factory requires 50 units per SKU, that’s 750 total units.

This capital multiplication surprises beginners. Simplify first orders: one or two colors, essential sizes only.

Fabric minimums exist independent of garment MOQs

Factories often require minimum fabric orders from textile suppliers. If your design uses unique fabric, you might need to commit to buying entire fabric rolls.

This adds hundreds to thousands in costs for custom fabrics. Using stock fabrics factories already have reduces minimums.

Realistic startup capital for branded clothing import

Budget $5,000-$15,000 minimum covering:

- Initial MOQ (300-500 units): $2,400-$7,500

- Samples and revisions: $200-$500

- Custom labels and packaging: $300-$800

- Shipping and duties: $500-$2,000

- Photography and content: $500-$1,500

- Store setup and marketing: $1,000-$2,000

Undercapitalization kills more clothing brands than bad designs.

Note: These are illustrative ranges based on typical apparel production. Actual costs vary significantly by garment type, factory, customization level, and destination market.

Why working with apparel-specialized sourcing makes sense

They understand garment construction and can evaluate quality

Evaluating knit quality, stitch types, seam finishing, and construction standards requires expertise most sellers lack.

Agents specializing in apparel know what good construction looks like and can catch quality issues before production.

They maintain relationships with garment factories

Apparel factories differ dramatically from general product manufacturers. Agents with established apparel networks know which factories excel at specific garment types.

You benefit from these relationships without years of building them yourself.

They handle tech pack creation and factory communication

Translating your design vision into technical specifications factories understand requires expertise. Agents bridge the gap between your concept and production reality.

They communicate in Mandarin about garment-specific technical details you couldn’t discuss effectively.

They conduct apparel-specific quality inspections

General product inspection differs from garment QC. Checking seam strength, stitching per inch, fabric weight, and construction quality requires specialized knowledge.

Professional garment inspectors catch issues DIY importers miss until customers complain.

They understand textile import regulations and compliance

Country of origin labeling, fabric content disclosure, care instruction requirements, and textile-specific customs documentation vary by destination market.

Agents familiar with textile imports ensure compliance, preventing customs disasters.

(See how Yakkyofy’s apparel sourcing handles the specific complexities of fashion brand creation.)

Realistic expectations for clothing brand timeline and success

Allow 4-6 months from concept to first sales

Design development, sampling, tech pack creation, production, shipping, and quality control take time. Rush orders cost more and create quality risks.

Plan accordingly. Fashion brands require patience and capital to get right.

Expect high initial return rates as you dial in sizing

Your first production run will have fit issues you didn’t anticipate. Some customers will return products. This is normal and expected.

Use return feedback to improve size specifications for subsequent orders.

Profitable usually requires 3-5 production runs

First order costs more per unit due to setup costs and learning curve. You’re also likely to over or understock certain sizes.

By runs 3-5, you’ve optimized sizing ratios, refined specifications, and reduced per-unit costs. Profitability compounds.

Most successful clothing brands took 12-24 months to profitability

Fashion brands require more capital and longer runways than other e-commerce. Success stories showing “$50K in month one” are exceptions or fiction.

Budget for extended timeline before achieving sustainable profitability.

The bottom line on importing branded clothing from China

Importing branded clothing offers higher margins and brand equity than generic dropshipping. But apparel has unique complexities that destroy unprepared sellers.

Sizing consistency, fabric quality evaluation, higher MOQs, textile import regulations, and seasonal inventory risks make clothing more challenging than other products.

Success requires understanding garment construction, having capital for proper MOQs, working with apparel-specialized factories, and maintaining patience through learning curve.

Most sellers should validate demand through generic dropshipping or print-on-demand first, then transition to imported branded clothing once demand is proven.

Use infrastructure designed for apparel. Don’t try creating fashion brands through general product sourcing. Work with partners who understand garment construction, quality standards, and textile regulations.

The infrastructure exists. The factories are ready. The question is whether you’re prepared for the capital requirements, timeline, and learning curve fashion brands demand.

Because building clothing brands is more complex than other product categories. But for those who get it right, the margins and brand value are worth it.

FAQ

How much does it cost to import branded clothing from China?

Budget $5,000-$15,000 for first order covering MOQs (300-500 units), samples, labels, packaging, shipping, duties, and setup costs.

What are typical MOQs for custom clothing?

300-1,000 units total depending on garment complexity. This must cover multiple sizes, multiplying actual inventory quickly.

How long does clothing production and import take?

4-6 months from initial design to receiving inventory, including sampling, production, QC, and shipping.

Do I need special licenses to import clothing?

Not for most countries, but garments require compliance with labeling regulations, fabric content disclosure, and textile-specific import requirements.

Can I start with smaller quantities than 300 units?

Some factories negotiate 100-200 units at higher per-unit costs. Print-on-demand is an alternative for testing designs before committing to MOQs.

How do I know if fabric quality is good?

Request fabric swatches. Check GSM (grams per square meter), feel hand texture, wash samples, evaluate durability. Work with partners who understand fabric grading.