The competitive advantage doesn’t come from finding products or running ads anymore. It comes from what happens after the “Buy Now” button gets clicked.

Fulfillment is where stores live or die. Fast, reliable order processing creates repeat customers and organic word-of-mouth. Slow, inconsistent fulfillment destroys brands before they can scale, no matter how good the marketing is.

This guide breaks down what dropshipping fulfillment actually means in 2026, why most stores hit a scalability wall around 10 orders per day, and how infrastructure separates sustainable businesses from temporary stores that collapse under their own growth.

What is dropshipping fulfillment?

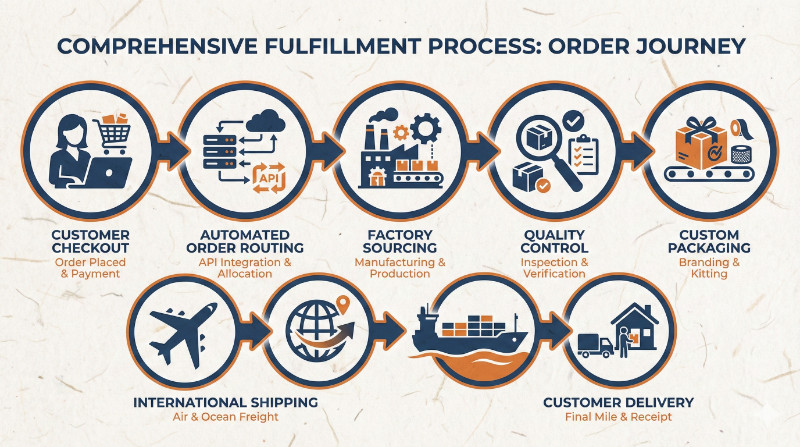

Dropshipping fulfillment is the complete operational process from the moment a customer places an order to the moment the product arrives at their door. It’s not just shipping it’s the synchronized management of sourcing, quality control, packaging, customs clearance, and delivery.

In traditional retail, you handle fulfillment yourself: products sit in your warehouse, you pack orders, you ship boxes. In dropshipping, a third party manages these operations while you focus on customer acquisition and brand building.

The fulfillment chain includes:

- Order routing from your store to the supplier

- Product sourcing from manufacturers

- Quality inspection before shipping

- Custom packaging application (if requested)

- International shipping and customs documentation

- Tracking number generation and customer communication

- Returns processing and restocking

Each step creates a potential failure point. One broken link—stockouts, quality issues, shipping delays, customs problems—damages customer trust and triggers refund requests, chargebacks, and negative reviews.

Learn the fundamentals of how dropshipping works and why fulfillment determines success

The sophistication of your fulfillment infrastructure determines how fast you can scale and how reliably you can deliver on brand promises.

The 3 pillars of a 2026 fulfillment strategy

Fulfillment infrastructure built for 2026 must support speed, automation, and brand differentiation. These three pillars separate scalable operations from systems that break under growth.

Speed and transparency: customers won’t wait 30 days

In 2026, customer expectations have converged around customer expectations have converged around fast shipping with transparent tracking: fast shipping with transparent tracking. Dropshipping stores competing with 20-30 day delivery times from China face systematic disadvantages.

Higher cart abandonment: Customers check estimated delivery before purchase. Long timelines kill conversion.

Increased support burden: Every day packages spend in transit generates “where is my order?” tickets.

Lower repeat purchase rates: Customers who wait 25 days for a product rarely order again, even if they’re satisfied with the product itself.

Competitive shipping strategies:

- Standard shipping: 10-15 days (baseline expectation)

- Premium special line: 5-10 days (competitive advantage)

- Express shipping: 3-7 days (premium positioning, subject to carrier availability)

Yakkyofy’s Premium Special Line typically delivers to major markets in 5-10 days for standard products, though actual delivery times vary by product type, destination, and customs processing. See current delivery estimates in your dashboard.

Transparency matters as much as speed: Real-time tracking with accurate delivery estimates reduces support tickets and builds trust. Customers tolerate slightly longer shipping if they know exactly when products will arrive.

Note: Estimated delivery times are based on average carrier performance and may vary due to customs processing, carrier delays, or peak seasonal volumes. Check current estimates for specific destinations in your dashboard.

Automated sourcing: never go out of stock

Manual sourcing creates bottlenecks that prevent scaling. When you’re processing 50+ orders daily, contacting suppliers individually, negotiating pricing, and managing inventory availability manually becomes impossible.

Automated sourcing infrastructure provides:

Real-time inventory visibility: Know stock status across multiple suppliers before customers order. Prevent selling products you can’t fulfill.

Instant B2B quotes: Upload product images, receive pricing from verified manufacturers in minutes without negotiating. Yakkyofy’s image recognition technology eliminates days of back-and-forth communication.

Automatic order routing: Orders flow from your store directly to suppliers without manual intervention. No copy-pasting order details, no missed orders, no human error.

Multi-supplier management: Distribute orders across suppliers based on stock availability, shipping speed, and cost optimization. Scale without dependency on single sources.

Predictive restocking: AI monitors sales velocity and triggers reorders before stockouts occur. Maintain buffer inventory in warehouses to eliminate processing delays.

Manual sourcing works when you’re processing 5-10 orders daily. At 50+ orders, it becomes a full-time job that prevents focusing on growth. At 200+ orders, it’s operationally impossible.

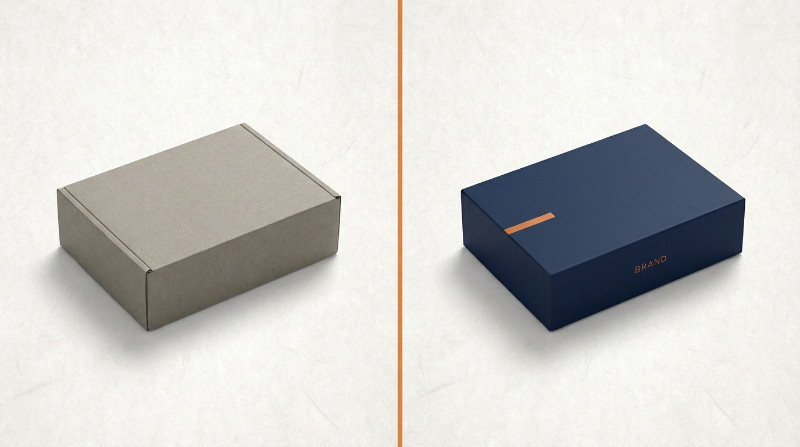

Custom packaging: from anonymous boxes to brand assets

Generic packaging with Chinese characters tells customers they bought from a dropshipper, not a brand. It communicates: “We’re intermediaries marking up commodity products.”

Custom packaging transforms the unboxing experience into a brand touchpoint that justifies premium pricing and creates social shareability.

What custom packaging includes:

- Branded boxes or poly mailers with logo and design

- Custom inserts with brand messaging, instructions, or offers

- Thank you cards personalizing the customer experience

- Product-specific packaging that protects items and looks premium

- No external Chinese markings or third-party branding

Why it matters for scaling:

Justifies higher prices: Customers expect to pay more for products that arrive in branded packaging. Perceived value increases.

Reduces returns: Professional packaging signals quality. Customers assume products will meet expectations before opening boxes.

Creates repeat customers: Memorable unboxing experiences drive repurchases and referrals. Generic packaging is instantly forgettable.

Enables social proof: Customers share unboxing videos when packaging looks Instagram-worthy. Free marketing amplification.

Yakkyofy offers private label and custom packaging for brands ready to differentiate beyond product selection. Learn how custom packaging transforms anonymous dropshipping into branded e-commerce

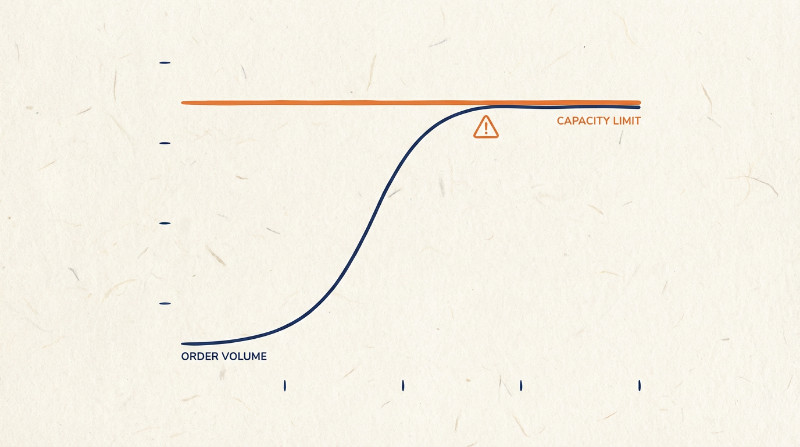

The “scalability trap”: why basic dropshipping fails

Most dropshipping stores hit a growth ceiling around 10-15 orders daily. Not because demand disappears—because operational infrastructure can’t support higher volume.

The pattern looks like this:

Phase 1 (1-5 orders/day): Everything works. You manually process orders through AliExpress or message suppliers directly. Customers receive products in 20-25 days. Some complain about shipping times, but conversion rates stay reasonable.

Phase 2 (10-20 orders/day): Manual processes become time-consuming. You spend 2-3 hours daily managing orders. Supplier communication lags. Occasional stockouts start happening because you don’t catch inventory issues fast enough. Customer service load increases.

Phase 3 (30+ orders/day): System collapse. You can’t manually process volume fast enough. Orders get missed. Products ship late. Customers get angry. Support tickets pile up. You’re working 12-hour days just maintaining operations, with zero time for marketing or growth.

Why this happens:

No centralized fulfillment: Managing orders across multiple AliExpress suppliers or random agents creates coordination chaos at scale.

Manual order processing: Copy-pasting order details for each transaction isn’t sustainable beyond tiny volumes.

Reactive problem solving: You only discover stockouts, quality issues, or shipping delays after customers complain.

No standardized quality control: Each supplier handles products differently. Consistency disappears as volume increases.

Limited supplier relationships: When you scale, suppliers prioritize large clients. Small, inconsistent orders get deprioritized.

The scalability trap isn’t about hitting maximum demand—it’s about operational infrastructure failing before you capture the market opportunity.

Read the full analysis: Why most dropshipping stores can’t scale past 50 orders daily

How to escape the trap:

Build fulfillment infrastructure that handles volume automatically. Centralized order management systems, automated supplier communication, predictive inventory monitoring, and quality control protocols that don’t require manual oversight.

This infrastructure costs more than manual processes at 5 orders/day. But it’s the only way to scale past 100 orders/day without hiring full-time operations staff.

EU compliance: VAT, IOSS, and customs duties

International fulfillment isn’t just logistics it’s navigating customs regulations, tax obligations, and import duties across dozens of jurisdictions.

European Union customers in 2026 face stricter enforcement of VAT collection and IOSS (Import One-Stop Shop) registration requirements. Sellers shipping to EU customers must comply or face packages held in customs and angry customers refusing to pay unexpected fees.

IOSS registration explained:

IOSS allows sellers to collect and remit VAT at checkout instead of customers paying customs fees on delivery. Registration centralizes VAT obligations across all EU member states through a single portal.

Benefits:

- Customers see total costs upfront (no surprise customs fees)

- Faster customs clearance (packages don’t wait for VAT processing)

- Better conversion rates (transparent pricing increases trust)

- Compliance with EU regulations (avoid penalties)

How it works operationally:

- Register for IOSS with an intermediary or tax advisor

- Collect VAT at checkout based on customer country

- Report collected VAT monthly through IOSS portal

- Remit taxes to appropriate EU tax authorities

- Include IOSS number on customs declarations

For sellers without IOSS registration:

Packages entering the EU trigger customs processing. Customers receive unexpected bills for VAT and handling fees (often €10-20 on top of VAT). Many refuse delivery. Others file chargebacks. Brand reputation suffers.

EU compliance: VAT, IOSS, and customs duties

Sellers shipping to EU customers on orders under €150 must comply with IOSS requirements or customers face unexpected customs fees at delivery, often €10-20 on top of VAT, which leads to refused deliveries and chargebacks.

There are two practical approaches:

Option 1 – Your own IOSS number (recommended) Register independently through the EU OSS portal or via a registered intermediary. Enter your IOSS number once in the Yakkyofy dashboard. From that point, all EU shipments include correct customs documentation automatically no additional cost per order.

Option 2 – Carrier IOSS service Some carriers offer IOSS coverage for a small fee per shipment. Useful if you’re testing EU markets before committing to full registration. Yakkyofy’s operations team can assist with the technical setup. For VAT obligations, registration requirements, and reporting, consult a qualified tax advisor requirements vary by business structure and country of registration. Note: Yakkyofy is an Italian company and issues EU-compliant invoices. VAT registration and IOSS compliance remain the seller’s responsibility.

Why Yakkyofy infrastructure supports scalable fulfillment

Yakkyofy isn’t a software platform that connects you with suppliers. It’s a publicly traded Italian company (Euronext Growth Milan) with direct factory relationships, proprietary warehouses, and end-to-end infrastructure that removes every operational failure point.

What separates infrastructure from aggregator platforms:

Direct factory relationships: Yakkyofy sources from verified manufacturers across 12 Chinese provinces. No intermediaries marking up products. No supplier roulette where quality varies by order.

Proprietary warehousing: Products stocked in Yakkyofy’s China warehouse enable faster processing compared to ordering from individual suppliers.

365-day operations: Yakkyofy maintains operations during Chinese New Year and major holidays, minimizing disruptions during critical selling periods.

Automated fulfillment system: Orders flow from your Shopify/WooCommerce store directly to Yakkyofy without manual processing. Tracking numbers generate automatically. Customers receive updates at every stage.

Image recognition sourcing: Upload product photos to receive quotes from manufacturers, typically within 24-48 hours.

Quality control infrastructure: Pre-shipment inspections with photo documentation. Defective products never reach customers. Report-based verification for high-value items.

Custom packaging and private label: Brand your products with custom boxes, inserts, and labels. Transform generic dropshipping into branded e-commerce.

EU compliance built-in: IOSS registration, VAT collection, customs documentation handled automatically. Italian invoicing meets European business standards.

Transparent tracking: Real-time visibility into order status from manufacturing through delivery. Customers see progress without contacting support.

Scalable architecture: Infrastructure scales from stores processing 10 orders daily to high-volume operations, with service tiers appropriate to each business size.

The operational difference:

Most dropshipping platforms are marketplaces connecting sellers with suppliers. When problems arise, stockouts, quality issues, shipping delays, you’re stuck negotiating between supplier and customer with no leverage.

Yakkyofy owns the entire process. Factory relationships, warehouse operations, quality control, shipping logistics, customs clearance. One point of contact, full accountability, professional service standards.

This matters most when scaling. At 10 orders/day, you can manually solve problems. At 100 orders/day, systemic issues require infrastructure, not individual effort.

Ready to build fulfillment infrastructure that scales?

Yakkyofy provides instant B2B quotes, automated order processing, and transparent shipping to 100+ countries.

Get started in minutes, not days.

Faq

How long does fulfillment take in 2026?Processing typically takes 3–5 business days for in-stock items, plus shipping time based on selected service level.

Can I use my own branded packaging?Yes. Custom packaging, private labeling, and branded inserts are available for Premium and Premium+ plans.

What if a package is stuck in customs?

Customs delays are minimized when IOSS documentation is correctly attached to shipments. If you’ve entered your IOSS number in the Yakkyofy dashboard, it’s included automatically on EU declarations. For persistent delays, contact your carrier with the tracking number and IOSS documentation as reference.

Do I need my own warehouse to scale?

No. Modern fulfillment services offer integrated warehousing, allowing you to scale without investing in private storage.

How are returns handled?

Returns are sent to the provider’s local warehouse, inspected, and restocked when resellable, reducing losses and customer friction.

Can fulfillment services integrate with my store?

Yes. Fulfillment platforms provide API integrations with major e-commerce systems, enabling automatic order sync.