You found a winning product on AliExpress selling for $12. You’re selling it for $39 with decent margins. Business is good.

Then you discover the AliExpress seller is buying it from the factory for $4 and pocketing the $8 difference. You’re not competing on thin margins because the product is expensive. You’re competing on thin margins because you’re paying a middleman who adds zero value.

Every dollar you overpay on product cost is a dollar you can’t spend on marketing, faster shipping, or better customer experience.

They’re not smarter than you. They just cut out the middlemen.

Let me show you exactly how to buy directly from Chinese factories in 2026, avoid the scams that destroy beginners, and build relationships that give you sustainable cost advantages.

Why AliExpress sellers aren’t factories and what that costs you

Most dropshippers don’t realize they’re buying from resellers, not manufacturers. This ignorance is expensive.

AliExpress sellers are middlemen adding 20-50% markup

When you order from AliExpress, you’re typically buying from trading companies or resellers who source from factories, add their margin, and resell to you.

The “supplier” you’re working with has never manufactured anything. They’re arbitrage operators buying low from factories and selling high to foreigners who don’t know better.

That $12 product? The factory sells it for $4-$6. The AliExpress seller adds $6-$8 of pure margin. You pay the inflated price thinking it’s “wholesale.”

You have zero control over quality or consistency

AliExpress sellers aren’t manufacturers. They don’t control production. They buy from factories, sometimes changing factories without telling you if they find cheaper options.

One batch might be excellent quality. The next batch might use cheaper materials because the seller switched suppliers to save money. You discover this when customers complain, not before.

You’re at the mercy of decisions made by people you’ve never met optimizing for their profits, not your customer satisfaction.

Stock availability is unreliable

AliExpress sellers don’t manufacture products or maintain deep inventory. They buy from factories in small batches and hope to resell before restocking.

When demand spikes, they run out. When you need to scale, they can’t support volume. When you want 500 units, they tell you “wait 2-3 weeks” while they order from their supplier.

You’re building a business on someone else’s inventory management. That’s not a supply chain. That’s hope.

You can’t negotiate pricing or customize products

Try asking an AliExpress seller to reduce pricing for volume. Try requesting product modifications or custom packaging. Try negotiating payment terms.

They’ll either ignore you or quote ridiculous minimums because they don’t want to deal with it. They’re optimized for small transactions, not partnerships.

Real factories negotiate. Real factories customize. Real factories reward volume. But you can’t access real factories through AliExpress middlemen.

Discover why factory-direct sourcing is the only sustainable model for scaling past six figures.

What buying directly from Chinese factories actually means

Let’s clarify what “factory direct” really means versus marketing hype.

You work with actual manufacturers who produce the goods

Real factories have production equipment, workers, raw material suppliers, and quality control processes. They make products, not resell them.

When you buy from a factory, you’re buying from the source. No markup layers. No middlemen taking cuts. No resellers changing suppliers without your knowledge.

This doesn’t mean you contact factories directly yourself. It means your sourcing partner works with verified manufacturers, not trading companies pretending to be manufacturers.

You access wholesale pricing intended for bulk buyers

Factories price for volume. Their quotes assume you’re a business ordering hundreds or thousands of units, not a consumer buying one item.

This is why factory prices are dramatically lower than retail or even AliExpress “wholesale” prices. They’re not offering you a special deal. They’re offering you normal B2B pricing.

But you need to order in reasonable quantities. Factories won’t sell you 5 units at bulk pricing. The economics don’t work for them.

You can negotiate based on volume and relationship

Once you’re ordering consistently, you have leverage. You can negotiate lower unit costs for higher volumes. You can request payment terms. You can ask for product customizations.

Factories want reliable customers who order regularly. If you’re that customer, you become valuable to them. They’ll work with you.

This relationship doesn’t exist with AliExpress resellers. They don’t care if you order once or 100 times. You’re just another transaction.

You control quality standards through direct communication

Working with factories means you can specify quality requirements, request pre-production samples, conduct inspections, and hold them accountable for defects.

When issues arise, you’re talking to the people who made the product, not middlemen who have no control over production.

This dramatically improves product consistency and reduces quality disasters that destroy customer trust.

The realistic challenges of buying from Chinese factories yourself

Direct access sounds great until you try it alone. Then you discover why most people use intermediaries.

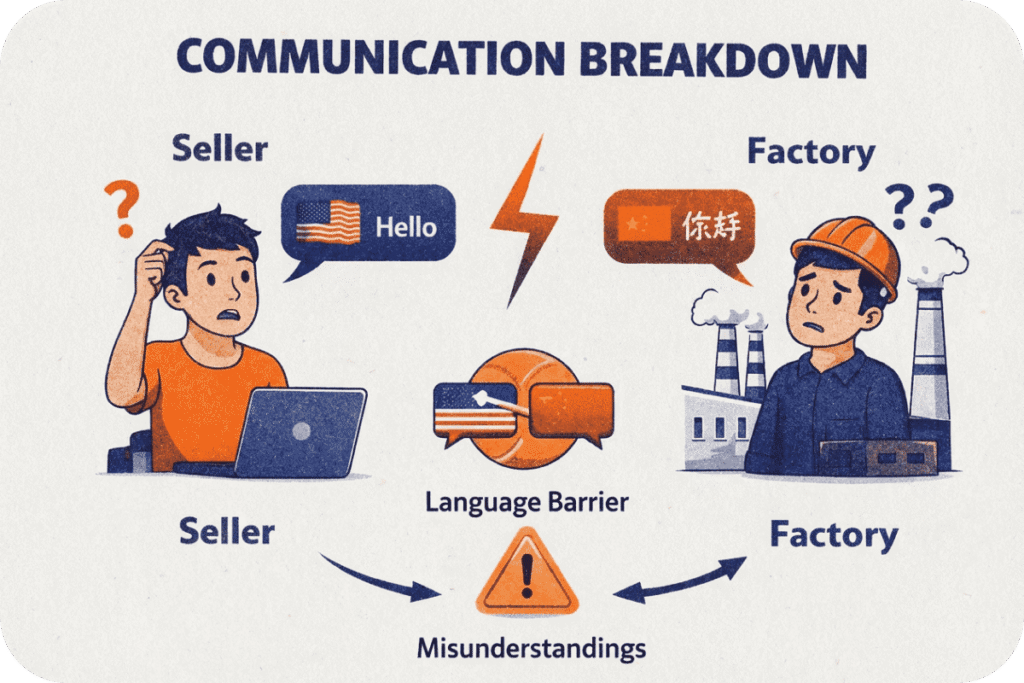

Language and cultural barriers create constant miscommunication

Most factory owners and sales managers don’t speak fluent English. Technical product discussions through broken English and Google Translate lead to expensive misunderstandings.

You ask for one thing. They understand something different. Production happens. You receive products that don’t match your expectations. Now you’re stuck with inventory you can’t sell.

This isn’t malicious. It’s just communication breakdown across languages and business cultures.

Finding legitimate factories among thousands of scams

China has millions of manufacturers. It also has millions of trading companies claiming to be manufacturers, scammers running fake operations, and opportunists looking to take deposits and disappear.

How do you verify a factory is legitimate? How do you know they actually produce what they claim? How do you avoid sending $5,000 to a company that vanishes the next day?

Due diligence requires visiting factories, checking business licenses, verifying production capabilities, and building relationships. Most sellers can’t do this from another country.

Minimum order quantities are higher than most sellers can afford

Real factories have MOQs because small production runs aren’t economically viable for them. You might need to order 500-1,000 units to access factory pricing.

If you’re just starting or testing products, this is too much capital risk. If the product doesn’t sell, you’re stuck with inventory you can’t move.

This barrier keeps many sellers buying from resellers who will sell smaller quantities at higher prices.

Payment terms and transaction risk

Factories typically want 30% deposit before production and 70% before shipping. Wire transfers are standard. PayPal protection doesn’t exist.

If something goes wrong, your money is gone. If they produce defective goods, you have limited recourse. If they take your deposit and don’t deliver, good luck getting refunds.

This transactional risk terrifies beginners and rightfully so. Scams are real and common.

Quality control requires technical knowledge

How do you inspect products for defects? How do you verify materials meet specifications? How do you catch problems before shipment?

Most sellers don’t have technical expertise to evaluate manufacturing quality. They trust factories to deliver what was promised and hope for the best.

This works until it doesn’t. Then you’re dealing with 500 defective units and no easy solution.

Learn why most successful sellers use sourcing agents instead of contacting factories directly.

How sourcing agents solve the factory-direct access problem

You want factory pricing without the complexity, risk, and operational burden of managing Chinese manufacturers yourself. Sourcing agents provide exactly this.

They have established relationships with verified factories

Professional sourcing agents have spent years building networks of verified manufacturers across different product categories and regions in China.

They’ve visited factories, checked certifications, evaluated production capabilities, and worked with them on hundreds of orders. They know which factories are reliable and which to avoid.

You benefit from relationships built over years without investing that time yourself.

They handle communication in Mandarin and English

Sourcing agents are bilingual and understand both Western business expectations and Chinese manufacturing culture. They translate not just language but intent.

When you need to communicate technical specifications, quality requirements, or delivery timelines, they ensure factories understand exactly what you need.

Miscommunication drops dramatically. Production accuracy improves. Problems get resolved faster.

They negotiate pricing on your behalf

Factories give better pricing to sourcing agents who bring consistent volume across multiple clients than to individual sellers ordering occasionally.

A sourcing agent might place 50 orders per month across different clients with the same factory. That volume creates leverage you don’t have alone.

They negotiate on your behalf using their collective volume, getting you pricing you couldn’t access individually.

They conduct quality inspections before shipment

Professional sourcing agents inspect products before they leave the factory. They catch defects, verify specifications match orders, and ensure quality meets agreed standards.

If problems are found, they work with factories to correct them before shipment. You never see the defective units. They get fixed or rejected at the source.

This quality control layer prevents disasters that destroy customer trust and create expensive return situations.

They reduce minimum order quantities through consolidation

Some sourcing agents maintain inventory of commonly requested products or can consolidate orders from multiple clients to meet factory MOQs.

This allows you to order smaller quantities while still accessing factory pricing. You might order 100 units instead of 500 because the agent is ordering 500 total across several clients.

The capital barrier drops significantly.

They handle logistics and customs compliance

Sourcing agents manage shipping arrangements, customs documentation, IOSS registration for EU customers, and duty calculations.

Your products arrive properly documented with correct customs declarations. Your customers don’t get surprise fees at delivery. Your shipments don’t get stuck at borders.

This operational complexity disappears from your plate.

See how Yakkyofy’s sourcing network provides factory access without the traditional barriers.

What factory-direct sourcing looks like with professional support

Let’s walk through the realistic process when you work with a sourcing agent.

You identify products you want to source

You’ve validated demand through dropshipping or market research. You know what products you want to sell and roughly what features and quality standards you need.

You submit sourcing requests to your agent with product details, target pricing, quality requirements, and volume estimates.

The agent identifies and vets appropriate factories

They search their factory network for manufacturers who produce that product category. They verify production capabilities, check previous quality records, and evaluate pricing.

They might present 2-3 factory options with different price points, MOQs, and capabilities. You choose based on your budget and requirements.

Samples are ordered and evaluated

Before committing to bulk orders, the agent orders samples from selected factories. You receive physical samples to evaluate quality, materials, and construction.

If something isn’t right, the agent works with the factory to adjust specifications. If the factory can’t meet requirements, you move to a different option.

You never commit to inventory without seeing exactly what you’re buying.

Production happens with quality oversight

Once you approve samples and place orders, production begins. The sourcing agent monitors progress, communicates with the factory, and coordinates inspections.

If problems arise during production, they handle resolution before products ship. You’re updated on progress but don’t manage day-to-day production coordination.

Products ship to warehouse or directly to customers

Finished goods ship to the agent’s warehouse for storage and fulfillment, or directly to your warehouse if you’re managing inventory yourself.

Customs documentation is handled correctly. Shipping is arranged through reliable carriers. Tracking information flows automatically.

You receive inventory ready to sell without navigating international logistics yourself.

Reorders happen at established pricing and terms

Once you’ve worked with a factory successfully, reorders are straightforward. Pricing is established. Quality expectations are known. Production timelines are predictable.

You scale volume without renegotiating everything from scratch each time.

The realistic costs and tradeoffs of factory-direct sourcing

Let’s talk honestly about what this actually costs.

Sourcing agents charge fees for their services

Professional sourcing isn’t free. Agents typically charge either a percentage of order value, a flat fee per order, or a combination.

These fees might add 5-15% to your product cost depending on order size and complexity. This sounds like a lot until you remember that AliExpress resellers were adding 30-50% markup.

You’re still saving money compared to buying from middlemen. You’re just paying a professional to navigate complexity instead of paying amateurs who add no value.

Minimum order quantities still exist but are lower

While factory MOQs might be 500-1,000 units, sourcing agents can often negotiate lower minimums or allow you to access bulk pricing at lower volumes through consolidation.

You might order 100-200 units instead of 500. This is still more capital-intensive than ordering one unit at a time from AliExpress, but dramatically more accessible than contacting factories directly.

This is the middle ground between pure dropshipping and traditional wholesale.

Lead times are longer than clicking “buy” on AliExpress

Factory production takes time. Sample approval, production, quality control, and shipping might take 3-6 weeks total.

This is longer than ordering in-stock items from AliExpress that ship in 2-3 days. You need to plan inventory and forecast demand instead of reacting to orders.

This requires more sophistication but enables better margins and quality control.

You trade transactional simplicity for strategic advantage

Buying from AliExpress is easy. Click, pay, done. Factory-direct sourcing requires communication, planning, and coordination.

You’re trading operational simplicity for cost advantages, quality control, and scalability. This tradeoff makes sense when you’re serious about building a real business, not just testing ideas.

Red flags that a “factory” is actually a reseller

Many companies claim to be manufacturers when they’re just trading companies. Watch for these warning signs.

They sell completely unrelated product categories

Real factories specialize. A factory that makes phone cases doesn’t also make fitness equipment, home decor, and kitchen gadgets.

If a “factory” offers thousands of completely unrelated products, they’re a trading company sourcing from multiple factories and reselling.

They can’t provide factory photos or certifications

Ask to see their production facility. Ask for business licenses or quality certifications. Real factories have these and will share them.

Trading companies will make excuses, provide generic photos, or deflect. They don’t have factories to photograph.

Prices are barely better than AliExpress

If their “factory prices” are only 10-15% lower than AliExpress, they’re not factories. They’re resellers with thin margins.

Real factory pricing should be 30-50% lower than retail platforms because you’re cutting out all the intermediary markup.

They can’t discuss manufacturing processes or materials

Ask technical questions about how products are made, what materials are used, or what quality control processes exist.

Real factories can discuss production in detail. Trading companies can’t because they don’t manufacture anything.

They’re unwilling to provide samples or conduct inspections

Factories are confident in their production quality and happy to provide samples or allow inspections.

Resellers don’t want you looking too closely because they’re buying from unknown sources and can’t guarantee quality.

What to actually expect from factory-direct pricing

Let’s set realistic expectations on costs.

Product costs drop 30-50% compared to AliExpress

If you’re paying $12 on AliExpress, expect factory pricing around $4-$7 depending on product complexity and order volume.

This is substantial savings that directly improves margins or allows you to invest in faster shipping, better packaging, or more aggressive marketing.

But total costs include more than product price

You need to factor in sourcing agent fees, shipping costs, customs duties, quality inspections, and sample costs.

When you add everything up, your total landed cost might be 20-40% lower than AliExpress, not 50%. This is still significant but not as dramatic as comparing product costs alone.

Volume discounts improve pricing over time

First orders at 100 units get one price. Reorders at 500 units get better pricing. Consistent monthly orders at 1,000+ units get even better pricing.

As you scale, unit costs continue dropping. This creates compounding margin improvement that pure dropshipping never offers.

Customization and branding add costs but create value

Adding your logo, custom packaging, or product modifications increases unit costs. But it also eliminates direct competition and allows premium pricing.

The cost increase is smaller than the revenue increase from brand differentiation, making it profitable to invest in customization.

The bottom line on buying directly from China at factory prices

Every dollar you overpay on product costs is a dollar you can’t invest in growth. Your competitors accessing factory-direct pricing have 30-40% cost advantages on identical products.

This isn’t a minor efficiency improvement. It’s the difference between struggling on thin margins and having room to invest in customer acquisition, faster shipping, and brand building.

But factory-direct access requires infrastructure. Language barriers, cultural differences, quality control, MOQs, and transaction risks make it impractical for most sellers to contact factories directly.

Sourcing agents solve this by providing factory access without the operational complexity. They handle communication, negotiation, quality control, and logistics while you focus on marketing and sales.

This isn’t free. Agents charge fees for their services. But those fees are dramatically lower than the markup you’re paying to AliExpress resellers who add zero value.

The question isn’t whether to source directly from factories. If you’re serious about building a scalable e-commerce business, you will eventually need to. The question is when to make that transition and who to work with.

If you’re still validating products and testing niches, AliExpress might be fine temporarily. But once you’ve identified winners selling consistently, every day you delay transitioning to factory-direct costs you money.

The infrastructure exists. The factories are waiting. The only question is whether you’re ready to stop paying middlemen and start building real competitive advantages.

Start Your dropshipping business

FAQ on buying directly from China at factory prices

How much cheaper is buying directly from factories versus AliExpress?

Product costs are typically 30-50% lower, though total landed costs (including agent fees, shipping, duties) might be 20-40% lower depending on order size and product category.

What are typical minimum order quantities when buying from factories?

Direct factory MOQs range from 500-1,000+ units. Sourcing agents can often negotiate lower minimums or provide access to bulk pricing at 100-200 units through consolidation.

How do I verify a factory is legitimate and not a scam?

Working with established sourcing agents who have vetted factory networks eliminates this risk. They’ve verified production capabilities, visited facilities, and worked with factories on hundreds of orders.

How long does factory production and shipping take?

Typically 3-6 weeks total including sample approval, production, quality control, and international shipping. This requires planning inventory versus reacting to orders.

Can I order samples before committing to bulk orders?

Yes. Before committing to bulk orders, sourcing agents request samples from selected factories. You evaluate quality, materials, and construction before approving production.

Do I need to speak Mandarin to work with Chinese factories?

No. Sourcing agents handle all communication in Mandarin and translate technical requirements accurately, eliminating language barriers.

What happens if products are defective or don’t match specifications?

Sourcing agents conduct quality inspections before shipment and work with factories to correct issues. Defective products get caught before shipping, not after customers complain.